I Main features:

- Servo feeding, stable and high re-positioning precision

- One time processing two pieces, high efficient

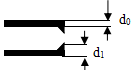

- Orbited cutter with spray lubricant, chipless cutting

- With online pre-stretching and beading, both pneumatic driving

- PLC control, HMI operation, simple and convenient

II Main technical data

|

No. |

Item |

Data |

|

1 |

Suitable copper tube |

Coil, TP1/2 (M/M2) |

|

2 |

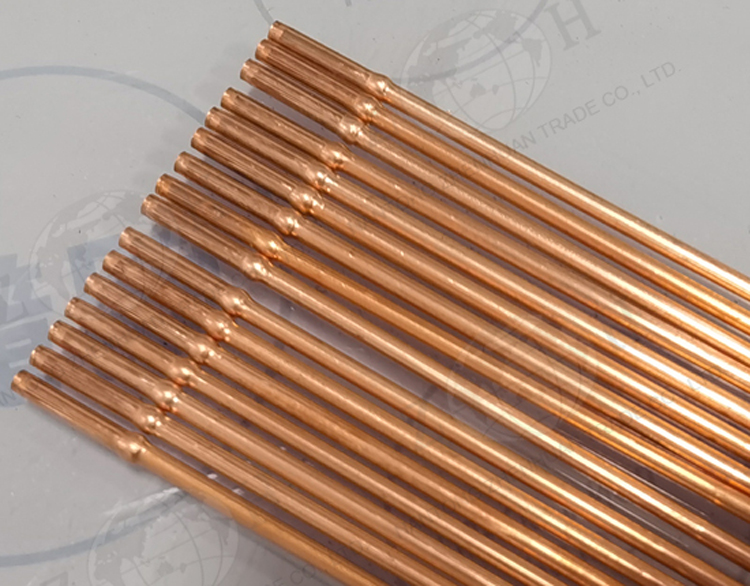

Suitable copper tube diameter range |

Ф2.0~Ф6.5mm |

|

3 |

Suitable copper tube wall thickness |

0.2~0.5mm |

|

4 |

Cutting length range |

40mm ~ unlimited |

|

5 |

Pay-off device |

only one transmitting bridge coils horizontal laying on ground |

|

6 |

Cutting pipes one time |

2 |

|

7 |

Cutting speed |

4 cuts per minute (@L=1000mm) |

|

8 |

One-time feeding stroke |

Continuous feeding, no length limit |

|

9 |

Cut-to-length tolerance |

≤0.3mm /1000mm |

|

10 |

Tube end ID reduction ratio |

f < 20% * |

|

11 |

Roundness of cut tubes |

Non-roundness ≤3% |

|

12 |

Length difference among two pieces |

≤0.5mm |

|

13 |

Surface condition after cut |

No apparent scratch, drawing marks; no burrs |

|

14 |

Compressed air |

0.5-0.7MPa |

|

15 |

Total electric consumption |

1.0kW |

|

16 |

Main machine dimension |

2800 x 1300 x 1600mm |

|

17 |

Pay-off device dimension |

2000 x 1000 x 2000mm |

* 1-When cutting length is less than 100mm, there will be no pre-stretching function.

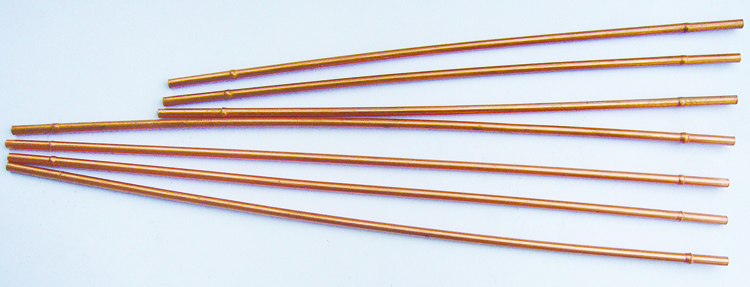

* 2- Tube end ID reduction ratio means:

f= (d1-d0)/d0%

f= (d1-d0)/d0%

III Main buildup:

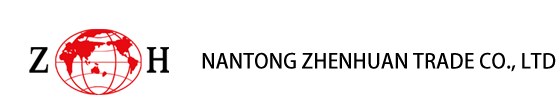

3.1 Pay-off device: one transmitting bridge for two capillary tubes (coil reels laying on ground only)

3.2 Straightening & rounding device: straightening deformation can be adjusted for different hardness copper tubes. When size changing, rounding wheel and straightening wheel will be changed.

3.3 Feeding device: driven by servo motor; Pulling and clamping dies are driven by enhanced pneumatic cylinders.

3.4 Beading device: forming by pneumatic, positioning is achieved by servo motor and PLC control system

3.5 Cutting device:

- Orbited cutting blade, 95% penetration tube wall thickness

- Pull-apart design driven by pneumatic, stable feeding and quick returning; feeding stroke of orbited cutting blade can be adjusted to assure same mouth shrinking rate.

- Equipped with lubricant spraying device for lengthening blade life.

3.6 Unloading table: prepared by Buyer.

3.7 All the clamping dies are made by chrome steel, quenched HRC 50

3.8 Control system: PLC + touch screen

IV Main configuration:

- PLC + HMI: Mitsubishi from Japan

- Pneumatic components: SMC from Japan / Pneulead from Italy

- Servo motor: Estun from China

- Limit switch: Autonics from Korea

- Ball screw: TBI from Taiwan

- Buttons & relays: IDEC from Japan / SIEMENS from China

- Main bearings: NSK from Japan

|capillary copper tube beading machine|capillary copper tube cutting machine|capillary copper tube straightening & cutting machine|

Products

Car Radiator Machines Car AC Condenser Machines Car AC Evaporator Machines Copper Radiator Machines Intercooler Machines Oil Cooler Machines Home AC Machines Refrigerator Making Machines Copper Fitting Machines Brazing Agent Machinery Nantong Zhenhuan Trade Co., Ltd. Add: No.243,Ninghai Road, Rugao City, Jiangsu Province, China 226500