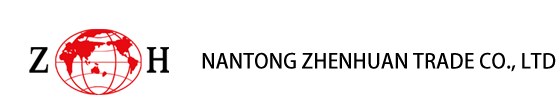

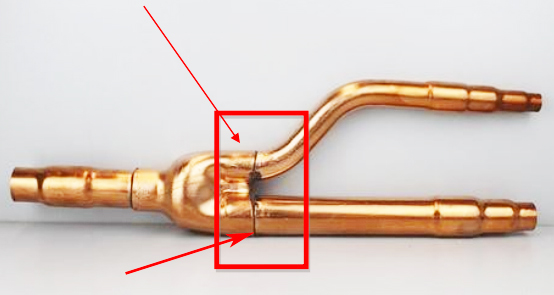

Typical Y-joint copper manifolds can be welded by this flame brazing machine:

This machine is designed in graduated turn-table structure, adopting flame brazing technology for welding copper tubes together.

For Y-joint manifold welding, this machine will have 6 stations, each station has one fixture:

- Station 01: blank tube loading

- Station 02: inspecting

- Station 03: flame brazing one end

- Station 04: flame brazing another end

- Station 05: cooling

- Station 06: unloading

Flame Brazing Machine Buildup:

1) Main body, turn-table and protection cover

2) Two sets flame brazing systems

3) Three sets auto welding wire feeding systems

4) One set water cooling system

5) Six sets tube fixtures

6) PLC control system

7) Gas pressure adjusting controller

8) Smoke exhausting system

Main features of copper tube flame brazing machine:

- Only manual loading & unloading, other actions automatic

- Stainless steel tube fixtures, free from deformation under high temperature

- Heating & cooling stations auto detecting, only work when there is part on fixture

- Welding torches are fine adjustable in all directions for different size parts

- Welding wires are fed automatically

- Nitrogen gas outfiring, quick and reliable

- Patent gas intelligent control system, gas pressure, flow and heating time can be preset

- Complete safety and alarming, auto stopping gas supply

Main technical data of copper tube flame brazing machine:

No.

Item

Data

1

Applicable parts

Copper /brass tube welding

2

Welding torch stretching cylinder stroke

175mm

3

Welding torch swinging range

5-10mm

4

Productivity

35 seconds per cycle

5

Electric supply

380V, 3phase, 50/60Hz

6

Motor power

1kW

7

LPG or CNG pressure required

0.065-0.12MPa*

8

Compressed air pressure required

0.5-0.55MPa*

9

Nitrogen gas pressure required

0.4-0.6MPa*

10

Machine dimension

About 2000 x 2000 x 2400mm

11

Weight

About 1000kg

*Notes:

1. If pressure is not within above mentioned range, pressure adjustor should be provided by end user.

2. LPG or CNG flow: about 1.5m3/h; Oxygen flow: about 2m3/h; Nitrogen flow: 0.5-1m3/h.

3. Phosphor brazing wire coil: diameter 1.2mm, 10kg/coil, 6 coils for one machine.

This copper tube flame brazing machine can be designed in different stations for other copper tubing parts:

Products

Car Radiator Machines Car AC Condenser Machines Car AC Evaporator Machines Copper Radiator Machines Intercooler Machines Oil Cooler Machines Home AC Machines Refrigerator Making Machines Copper Fitting Machines Brazing Agent Machinery Nantong Zhenhuan Trade Co., Ltd. Add: No.243,Ninghai Road, Rugao City, Jiangsu Province, China 226500